Hydraulic Solutions for Everyday Hydraulic Repair Shop Needs.

Our Featured Products

Nutbuster

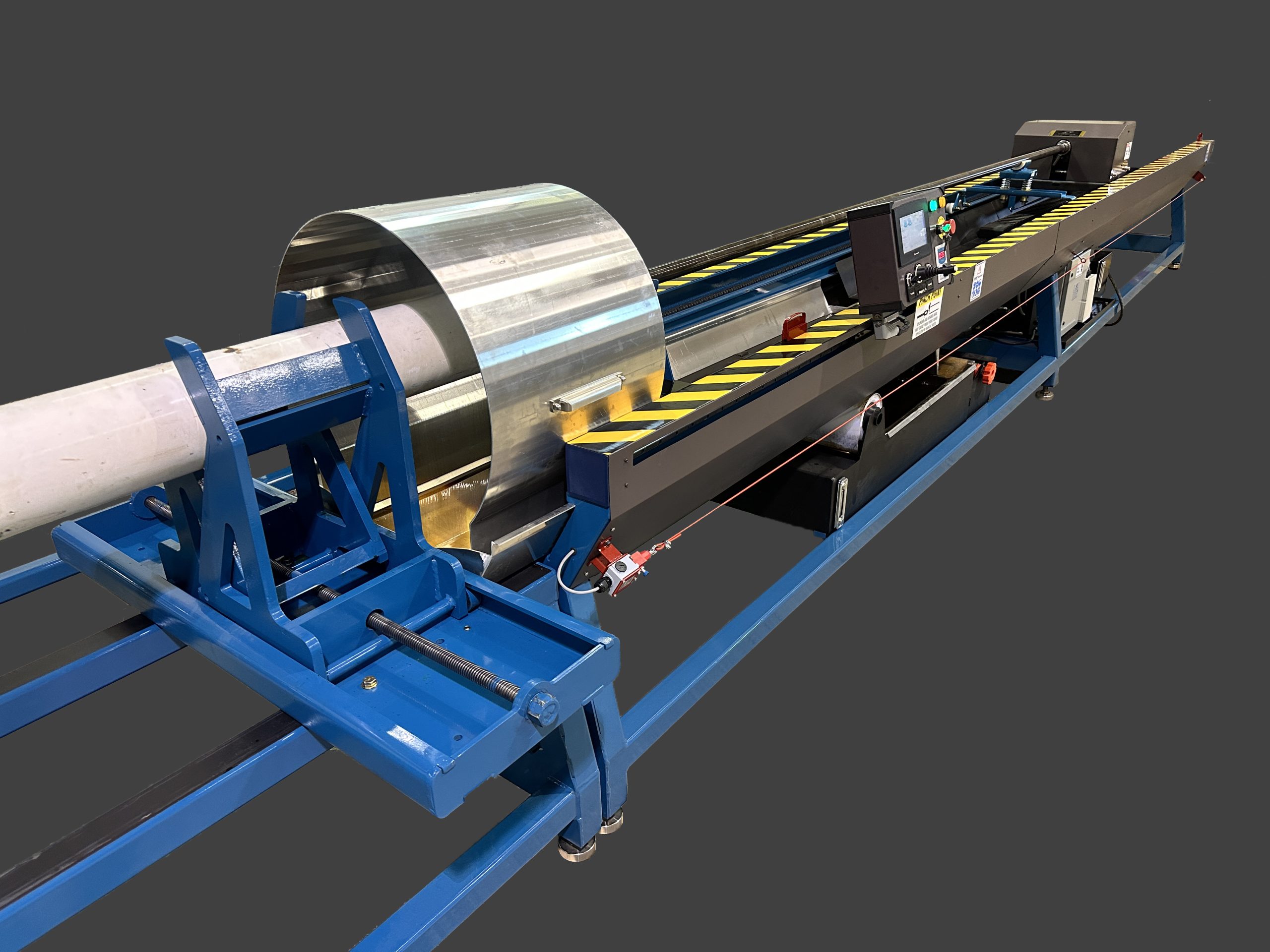

Hydraulic Cylinder Repair Bench

htw50/htw100

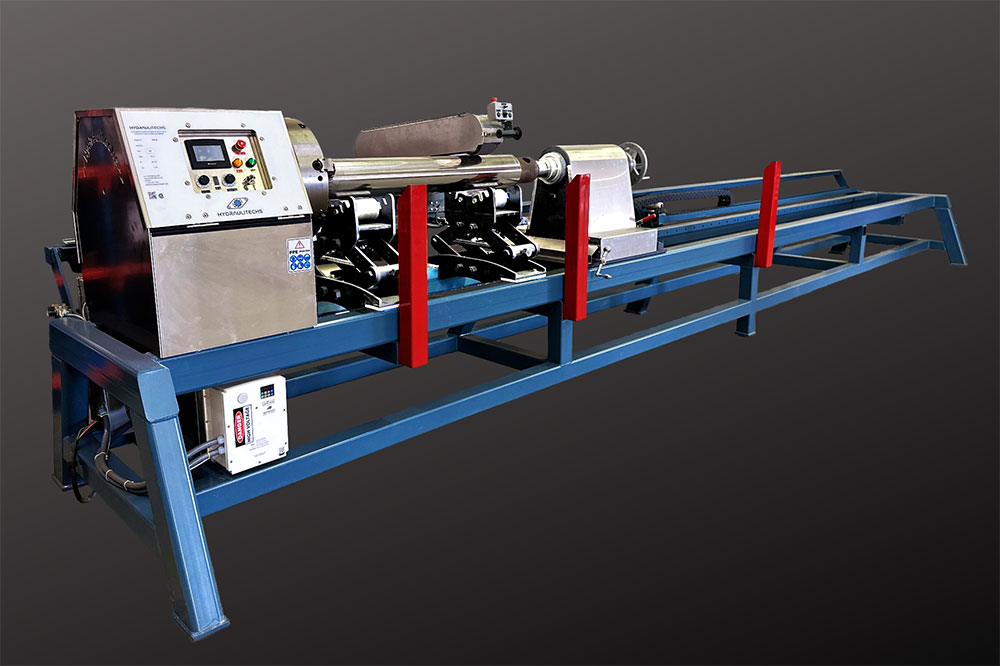

Honing Machine

Fully Automated Tube Honing Machine

Honix-WS-15/ Honix-WS-20

Rod Polisher

Automatic / Manual Machine

APR24/MPR24

Test Rig

Hydraulic Pump / Motor Test Stand

HTR500/HTR1000

Chain Vise Stand

Heavy Duty Chain Vise Stand

CH-S20

PORTABLE OIL TRAY

ALUMINUM / METAL

PTA20 / PTM20

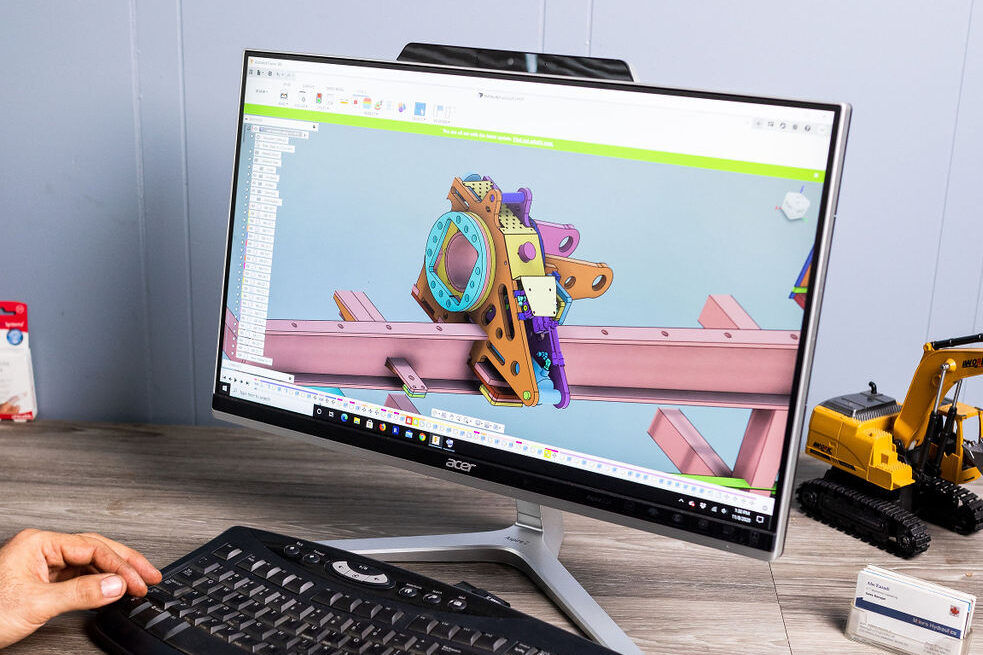

Engineered Design

- Custom Design

- User Friendly

- Easy Maintenance

Flexible and Affordable Pricing

- Enhance Your Hydraulic Shop Capabilities

- Flexible Price

- Quick Return on Investment

Warranty & Customer Service

At Hydraulitechs, we stand behind our products with reliable service and warranty support, ensuring your satisfaction every step of the way.

View Customer Product Videos

Customer Testimonials

What our customers are saying…

Hydraulitechs is very easy to deal with, and they were generous going the extra mile. We are very pleased with our purchase, and we are now saving money….as well as saving our backs!”

‘We purchased The Nutbuster and a cylinder bench from Hydraulitechs this year. We are VERY satisfied with the quality of the units and the pricing was very reasonable. The customer service we have received and continue to receive is beyond excellent! I highly recommend Hydraulitechs to anyone in the hydraulic repair industry that is looking for this type of tooling!’

‘Quick delivery of unit after ordering and follow up service has been great!

This is the 30′ unit with a 13′ cylinder on it.’

‘Back in the old days (right up until May 2021), breaking down a hydraulic cylinder was an incredibly labor- and time-intensive job at Moy Works. We had the know-how and we had the tools, but it could still take a full crew an hour or more to get a cylinder apart. Fortunately, those days are long behind us after the arrival of the Nutbuster Hydraulic Torque Wrench by Hydraulitechs.

With the Nut Buster, no hydraulic cylinder is too large for us to overhaul.’

We house a one of a kind ‘Nut Buster’ machine we call The Centrifuge. With over 50,000lb-ft of hydraulic torque and a huge 5m long bed, this awesome piece of equipment features Hydraulitechs ‘Nut Buster’ head with our bespoke bench and testing unit.

This gives us the capabilities to remove and retighten even the toughest of pistons and glands to manufacture specifications, as well as digitally testing each cylinder before returning to our customers.