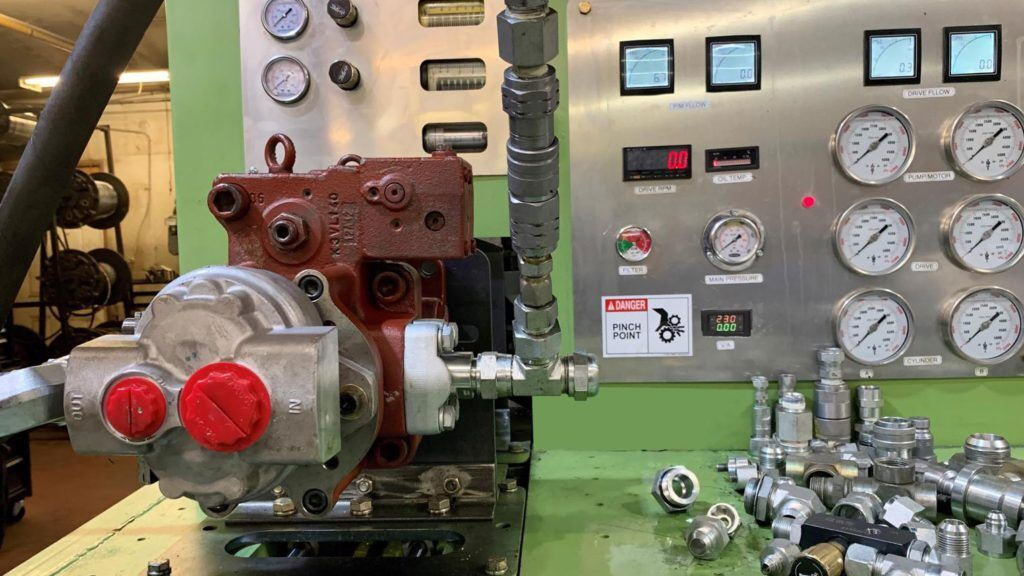

TEST RIG

HYDRAULIC PUMP / MOTOR TEST STAND

Test Rig / HTR500

The HTR 500 hydraulic test rig is a multi-functional universal test stand and designed for general shop testing.

Capable of testing an extensive range of hydraulic components such as hydraulic pumps, motors, valves, cylinders and other components.

Can test all makes and models of hydraulic components.

Component performance is determined by comparing test results with the manufacturer’s specifications.

Utilizing the benefits of the HTR 500 will give you peace of mind when you deliver products to your customers.

TEST ITEM METRICS AND CAPACITY

The HTR 500 is capable of testing components such as pumps, motors, drives, valves, cylinders, accumulators,

hydraulic concrete hammers, pressure relief/reducing valves, flow controls, steering units and flow dividers.

Test Rig

Component Types

- Cylinders: up to 6 GPM, 6000 PSI, all types

- Motors: closed loop/open loop

- Pumps: closed loop/open loop, up to 3 sections

- Hydrostatic pumps/drives

- Valves: 3-section, simultaneous

- Accumulators

- Flow control

- Flow dividers

- Hydraulic concrete hammers

- Pressure relief/reducing valves

Test Rig

COMPONENT SPECS

- Max weight 200 kg / 440 lbs.

- Max diameter 80 cm / 31 inch

- Max length 200 cm / 80 inch

Other Specifications

- 50 hp 3-phase electric motor

- 420 volt 3-phase, 55 amp

- 6 GPM @ 6000 psi

- 30 GPM @ 2500 psi

- 50 GPM @ 1350 psi

Auxiliary Electrical Supply

- PWM 12 volt (for test proportional valves)

- 12/24 DC outlet (for testing solenoid valves)

- Control station for running up to 3-stage valve independently

- Main flow and pressure

- Test item flow/pressure/power

- Electrical motor amp/voltage/power

- Test item electronic data acquisitions/monitoring for all pressure and some drain lines.

Universal Mount and Shaft Attachments

- Float spinning love joy shaft couplings with speed monitoring

- Easy pump/motor shaft attachments (all standard couplings supplied)

- Universal mounting system for components (accommodates SAE-A/B/C)

Hydraulic Quick Connections

- 3 case drain lines (1 flow and temp-monitored)

- 3 monitored return lines (pressure and flow)

- 3 suction lines

- 1 auxiliary charge pressure line (with adjustable and monitored pressure and flow) – this feature is utilized to help test pumps with charge line/drive with break line or small hydraulic components.

Other Main Features, include

- Oil Drain Bed for collecting spilled oil during test process

- Protective guard for spinning shaft and coupling

- Low profile test item fixture for easy handling

- 150 L (40 gal) tank with level/temperature monitoring for main pump

- 150 L (40 gal) tank for test item with filtration and heat/level monitoring

- Internal leakage test for hydraulic cylinders