Nutbuster

Hydraulic Cylinder Repair Bench/TORQUE MONSTER

HYDRAULIC MONSTER WRENCH

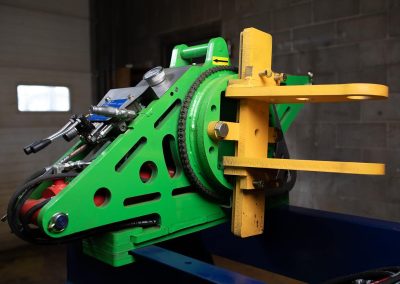

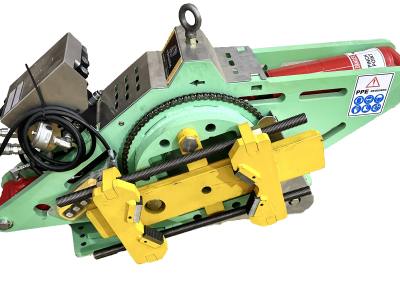

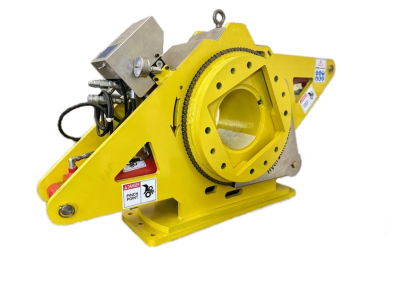

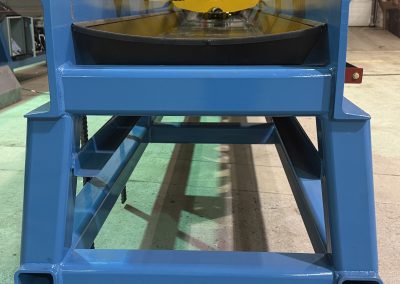

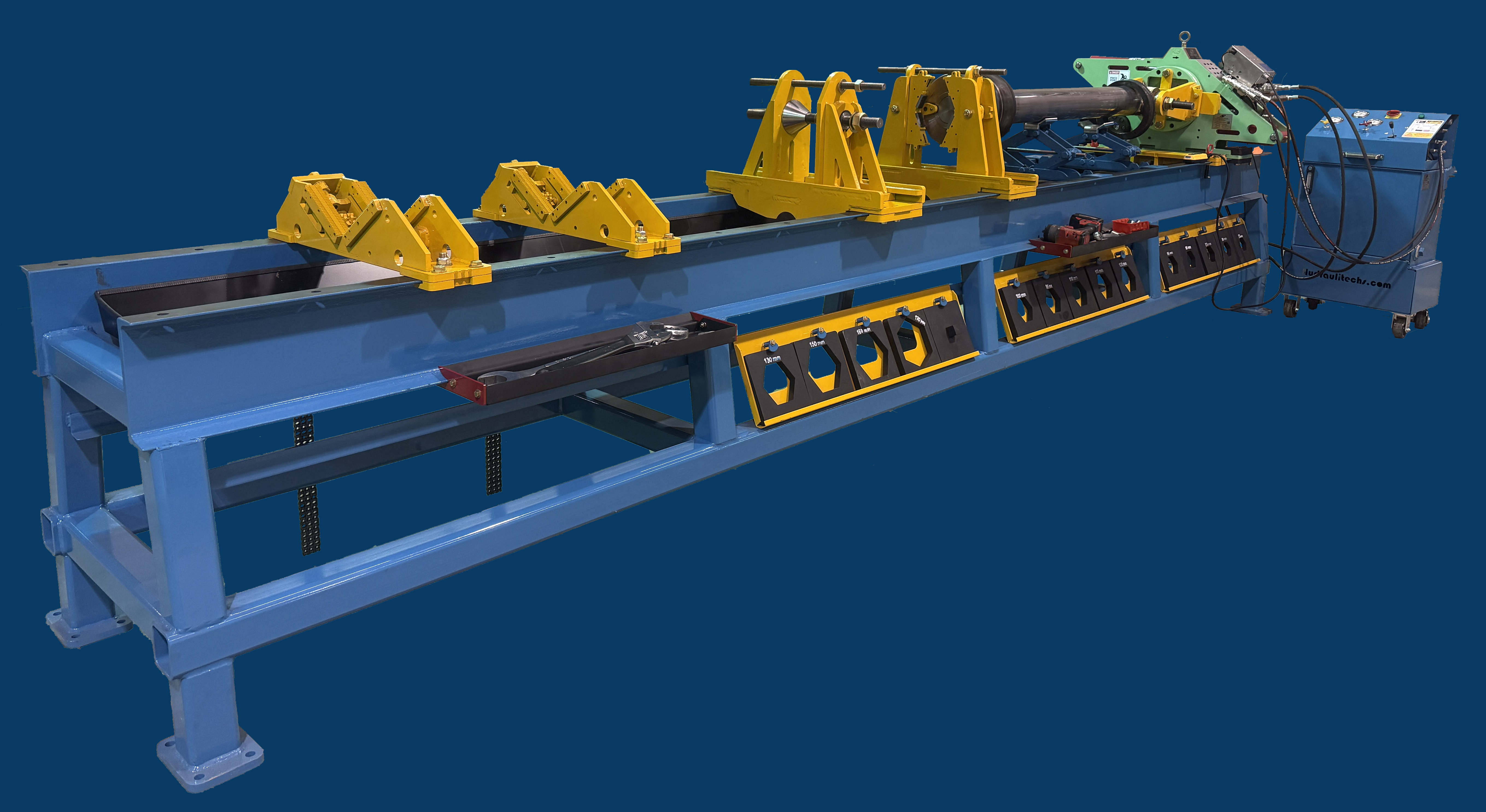

The Hydraulic cylinder repair bench/Nutbuster is designed to disassemble and tighten piston nuts and cylinder glands. Two counteracting cylinders generate cracking torque and a fast turning motor taking action to open the nut.

Nutbuster capabilities

The Nutbuster System is a premium hydraulic cylinder repair bench that includes the Nutbuster Head which generates the torque to disassemble the nuts and glands of heavy-duty hydraulic cylinders.

Who can benefit from the Nutbuster

The mining, oil and gas, forestry, marine, Hydraulic shops and construction industry benefit from the Nutbuster™.

Warranty & Customer Support

The Nutbuster head and repair bench has life time warranty. Customers also receive standard safety, upkeep and operations manuals and assistance. This product is proudly engineered, produced and assembled in Canada.

Nutbuster

Features

- Base swivel

- Electric control valve

- Wired remote control

- Pressure-torque chart

- Hydraulic motor with 600 ft-lb

- Self-locking hex plates

- Capable of attaching to the Back Eye Holder

- Customizable table

- Push/Pull function

- Spanner/Pipe wrench

- User friendly heavy Chain vise

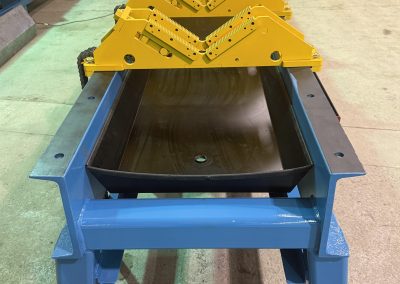

- Oil tray

NUTBUSTER - HTW50 SPECIFICATIONS

- MECHANICAL

Int. Head Torque 50,000 lb-ft

Hydraulic Motor Torque 600 lb-ft - TABLE (customizable)

Standard with complete tray 20 – 50 ft - STANDARD POWER UNIT (Optional)

Power Requirements 5 HP

Standard Voltages 220, 1-Phase

Tank 15 Gallon

Pressure 2,500 – 3,000 psi

Flow 2-5 gal/min - OPTIONAL POWER UNIT

TLP/THP Test unit, more detail.

NUTBUSTER - HTW100 SPECIFICATIONS

- MECHANICAL

Int. Head Torque 100,000 lb-ft

Hydraulic Motor Torque 600 lb-ft - TABLE (customizable)

Standard with complete tray30 – 40 ft - STANDARD POWER UNIT (Included)

Power Requirements 7.5 HP

Standard Voltages 220, 1-Phase

Tank 20 Gallon

Pressure2,500 -3,000 psi

Flow 2-5 gal/min - OPTIONAL POWER UNIT

THP Test unit, more detail.

Nutbuster Models

HTW50: Economic option

The HTW50 model is suitable for most of the hydraulic shops and is capable of applying 50,000 ft/lb torque.

HTW100: Extra heavy duty

The HTW100 model is designed for heavier jobs and is capable of appyling 100,000 ft/lb torque.

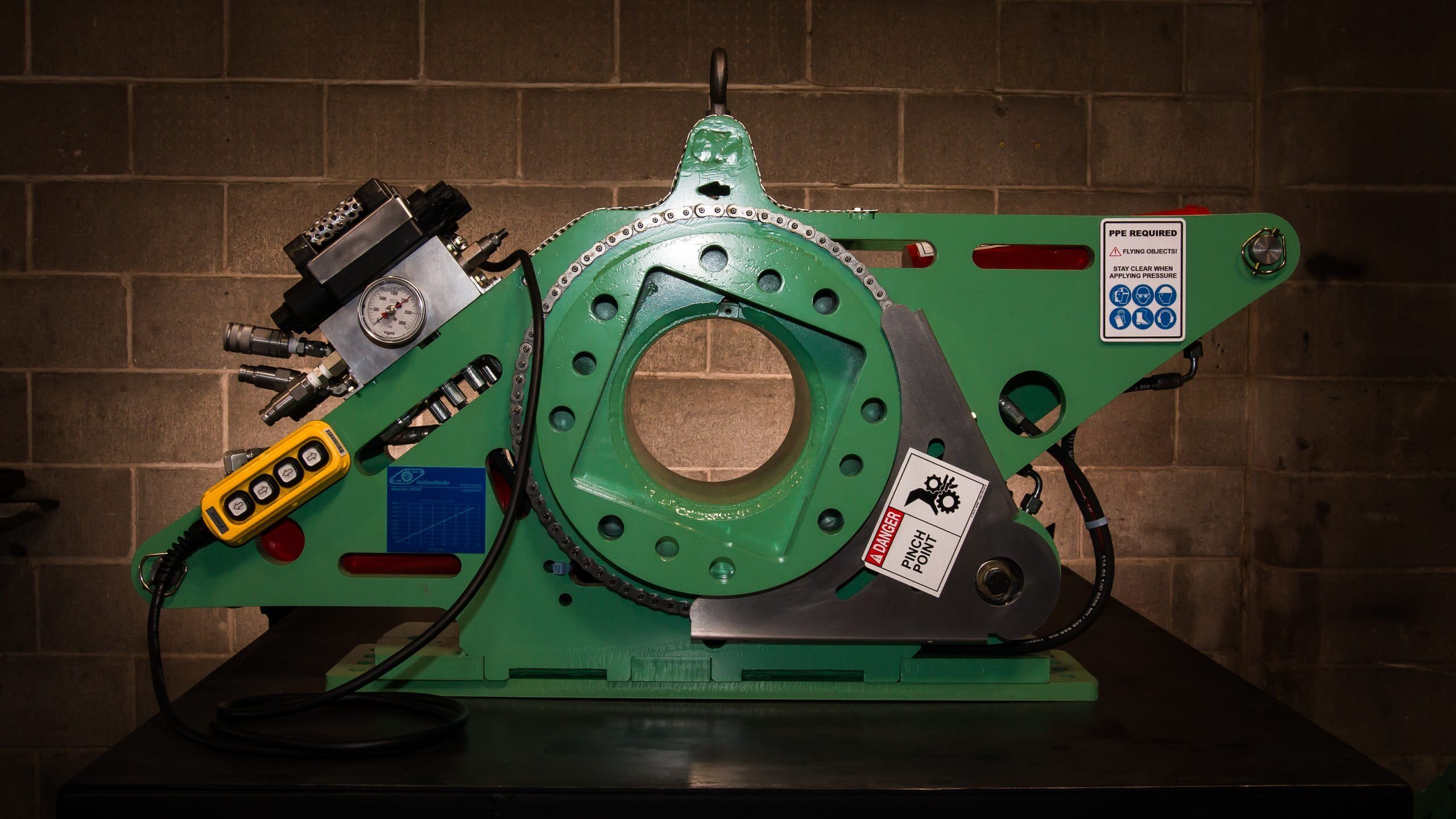

Nutbuster Head Details

- The Nutbuster operates through an electric control valve that is mounted on the Nutbuster Head, running by wired remote control.

- The control valve controls the 2 hydraulic cylinders, the hydraulic motor and a push/pull cylinder.

- The Nutbuster head sits on a swivel base.

Customizable & Affordable

We commit to support all business sizes and budgets.

- The Nutbuster Assembly comes standard with all attachments and accessories.

Customer Product Options

- Remove items based on budget needs.

- Build the bench with the supplied copy of Hydraulitech’s engineering plans.

- Purchase the optional push/pull cylinder, a power unit, and a wireless digital control panel.

- Hydraulitechs will customize the Nutbuster’s base according to customers’ existing table.

Attachments

The Hydraulic cylinder repair bench assembly includes the Nutbuster Head and the following tools or attachments. With the assembly, customers are able to safely and efficiently disassemble and assemble practically every type of hydraulic cylinder. The hydraulic cylinder repair bench/Nutbuster assembly is a complete service system for rebuilding cylinders.

Other Specifications

- 1. Hex Plates

- 2. Front Eye Holder

- 3. Gland Wrench Set

- 4. Back Eye Holder

- 5. Lifting Jack

- 6. Push/Pull Plate

- 7. Heavy Duty Chain Vise

- Hex plates are nut sockets that lock into the hex plate holder and make it easy to remove and install nuts.

- HTW50 Plates are available in 12 sizes, ranging from 80mm to 170mm.

- HTW100 Plates are available in 12 sizes, ranging from 85mm to 280mm.

- The HTW50 plates come in 9”x9”x1” thick plates.

- The HTW100 plates come in 13”x13”x1” thick plates.

- A 1″ and 1.5” socket drive plate is also available.

- Custom Hex Plates are available on demand.

- The attachment holds the front eye of the cylinder as the nut is removed.

- The holder is adjustable up to 20” (HTW50) and 30″ (HTW100).

- Contains a clevis for the front eye of the push/pull cylinder.

- The 2-in-1 gland wrench set is an attachment designed as a pipe wrench and spanner wrench.

- The pipe wrench’s jaw teeth grip by digging into the material of the cylinder. This provides a secure 4-point grip to ensure the end caps do not rotate.

- The pipe wrench accommodates glands up to 14”.

- The front and side spanner wrench grip the holes on the face or circumference of the end caps of the cylinder.

- Pins are adjusted to match the holes in the end cap.

- The spanner accommodates glands up to 20”.

- This attachment is installed onto the rotating head of the Nutbuster through fastening bolts.

- With the use of a pin bolt, the back eye of the cylinder is secured to the Nutbuster.

- With the cylinder in a fixed position at the Gland Wrench Set, the Back Eye Holder rotates with the head of the Nutbuster to loosen the gland.

- The Back Eye Holder accommodates cylinders with the back eye up to 20” (HTW50) and 30″ (HTW100).

- The easy-to-slide lifting jacks consist of aluminum pads that help align the ride or tube before torque is applied.

- Two (2) 2.27-tonne lifting jack comes standard with the Nutbuster HTW50 System. Optionally, 5-tonne jacks are available for heavy jobs.

- Two (2) 5-tonne lifting jack comes standard with the Nutbuster HTW100 System.

- This attachment, in conjunction with a push-pull cylinder, is used to pull or push the rod assembly in or out of the cylinder.

- The plate is connected to the work bench and to the back eye of the push/pull cylinder.

- This plate is designed to accommodate a 3” back eye from the push/pull cylinder.

- The heavy duty chain vise, which is mounted to the work bench, is used to secure and to work on cylinders .

- Once secured, the cylinder will not move as it is disassembled or as it’s gland is removed.

- The vise is mounted to the bench and is easy to setup for each job.

- The chain vise secures cylinders up to 20” (HTW50) and 30″ (HTW100).

TLP/THP TEST UNIT Specifications

The test unit is a valuable addition, allowing you to test hydraulic cylinders on the Nutbuster table after repair. Conveniently, it is on wheels, providing mobility for ease of use. We provide two options:

TLP, TEST UNIT

| TLP | |

| Pressure | 2500 – 3000 PSI |

| Pump capacity | 2 – 5 GPM |

| Hydraulic oil | HV32 |

| Power | 5 HP,110 – 220 V, AC line |

| Tank capacity | 25 Gallons |