HONING MACHINE

FULLY AUTOMATED TUBE HONING

-Fully Automated Tube Honing Machine- HONIX-WS-15/ HONIX-WS-20

The HONIX-WS-15/20 design is innovative and revolutionary, making it stand out from other honing machines in the hydraulic repair industry. It is designed by experienced engineers who removed the hassles in the honing process. Use the HONIX-WS-15/20 to increase the quality and productivity of your operation.

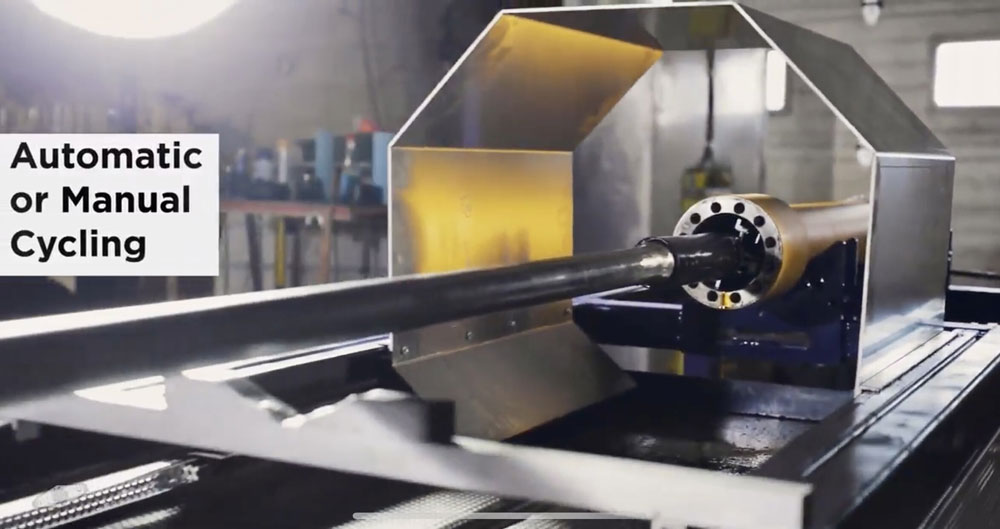

Automatic or Manual Cycle

- Increase operator productivity

- Faster cutting rates

- Consistent quality

- Time-saving

- User-friendly

- Customer satisfaction

- Reduce material waste

- Decrease part rejects

- Low maintenance

Honing Machine

specifications

- Voltage Max 410V,10Hp,3Ph,50/60 HZ,30A

- Travel Max 15 ft or 20 ft , depending on the model

- Travel Speed 100 ft/min

- Bore Range 2.5”-21”

- Max Honing Torque 500 ft/lb

- Max Spindle Speed 225 rpm

Honing Machine

Consumables

- Hydraulic Oil Multi Grad 32/10 Gal

- Honing Oil 40 Gal

- Honing Head ANR160A

- Fuse FRZ ATDR30 GLS/600V/30A (#3)

- Fuse 5A (#1)

- Fuse 3A (#6)

- Fuse 1A (#3)

- Filter Paper media coolant roll (#1)

- Oil Filter (Power Unit) Buyers HFA51025

Innovative Design of the Honing Machine

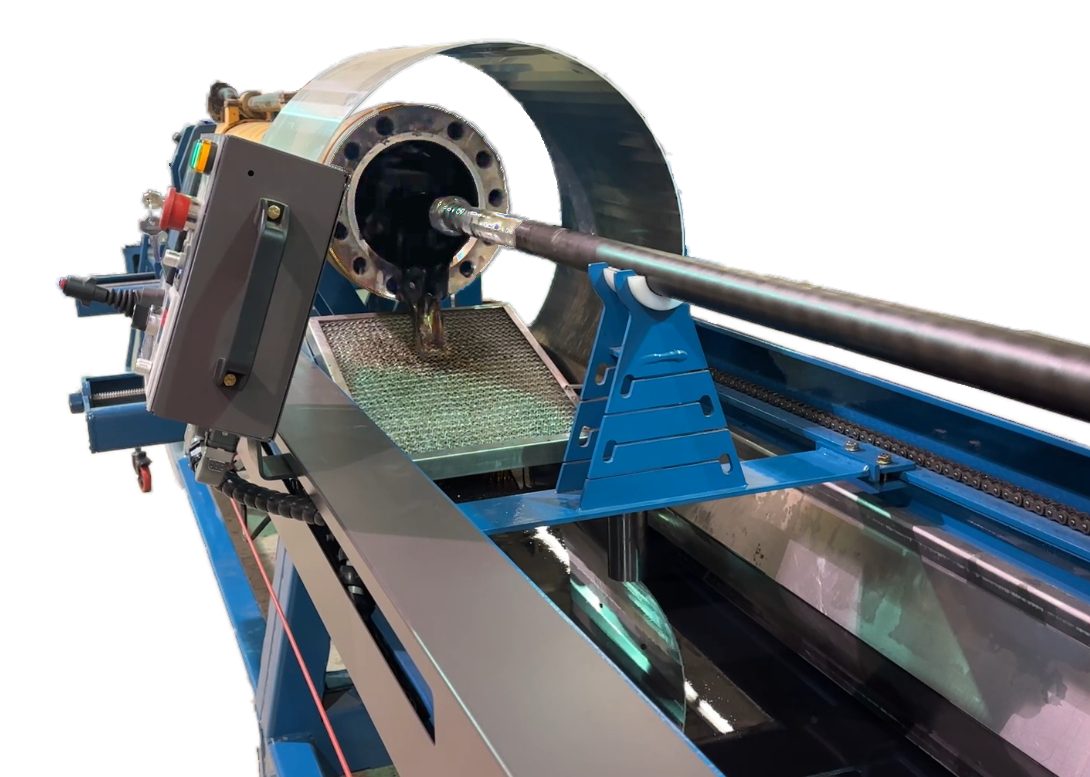

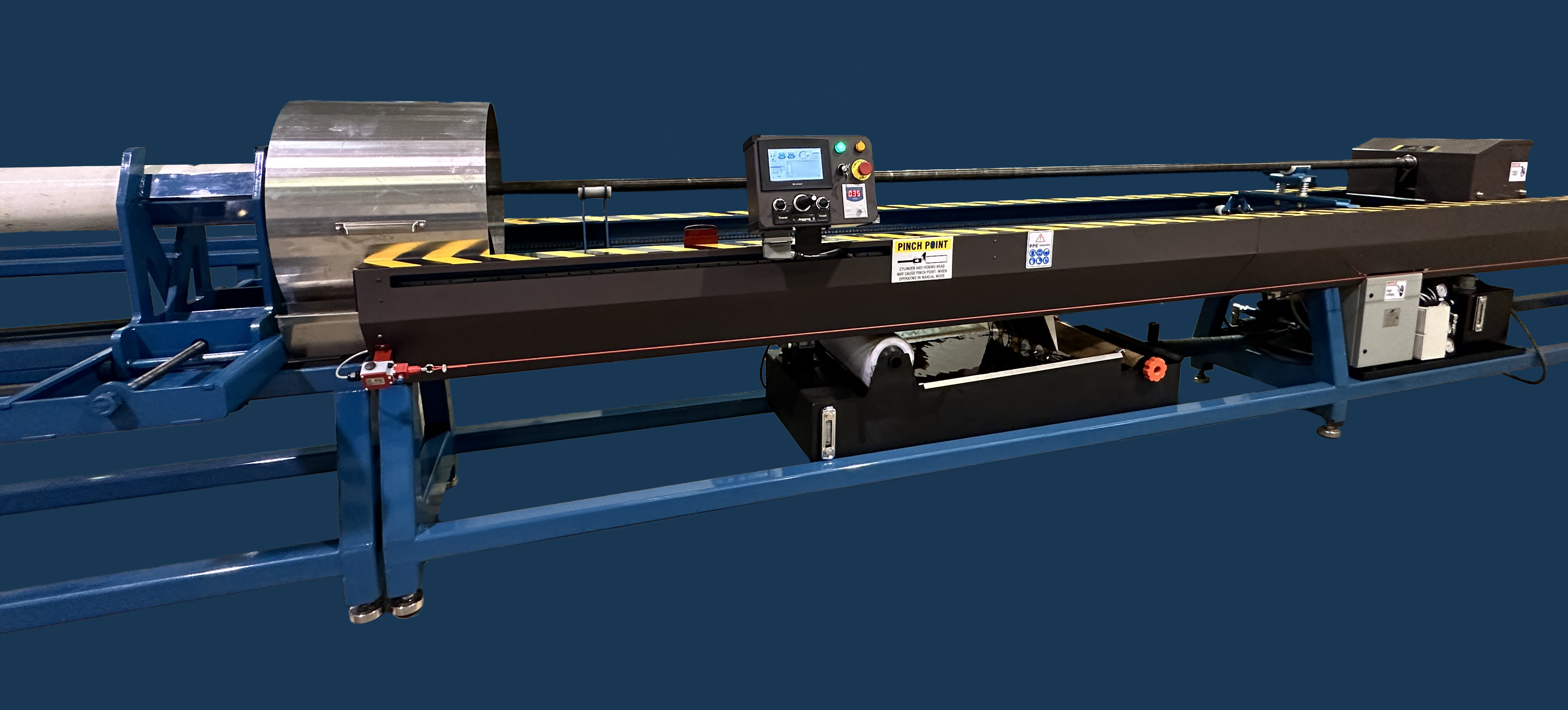

The HONIX 15/20 is a fully automated honing machine with electric over hydraulic design.

- The hydraulic power unit is mounted below the frame that drives two hydraulic motors for the stroker and the honing head.

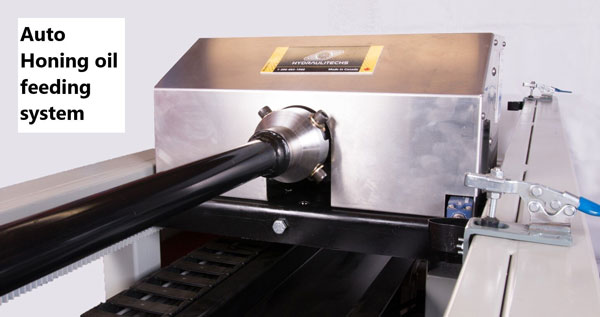

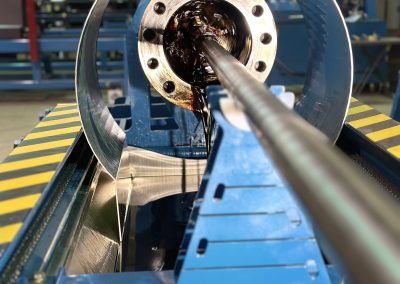

- The honing oil centrifugal pumping system directly feeds the oil to the abrasive head media via the drive and feed assembly.

- This innovative design does not require connecting a hose to lubricate the tube. The Operator can start honing without maintaining proper feed during the honing process.This is possible through a patent-pending constant-torque clutching mechanism.

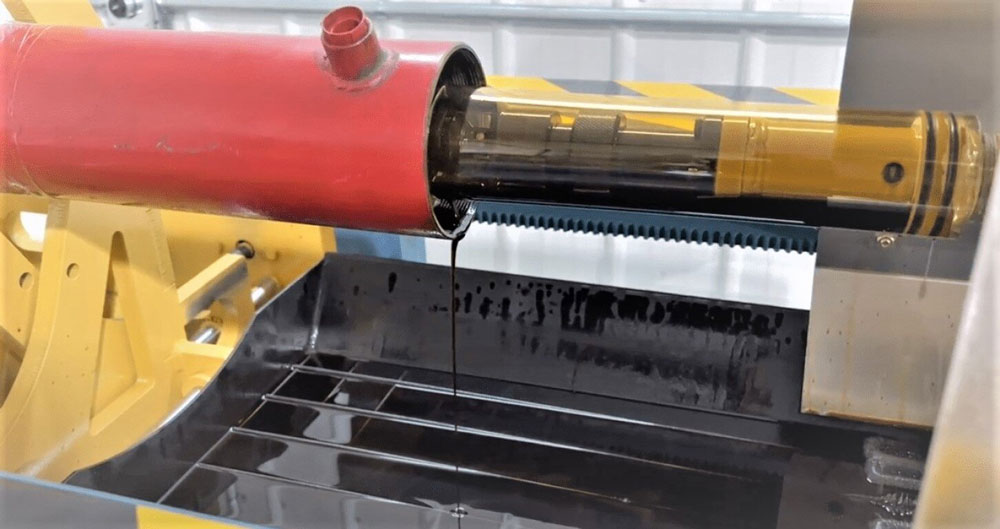

- The used honing oil is recycled through a 3-stage filtration process, thereby preventing galling between the workpiece and the tool.

- This ensures maximum cutting rates, long abrasive media life, and quality results.

Honing Machine Features

AUTO HONING OIL FEEDING SYSTEM

The honing oil is directly fed to the abrasive head media via the drive assembly.

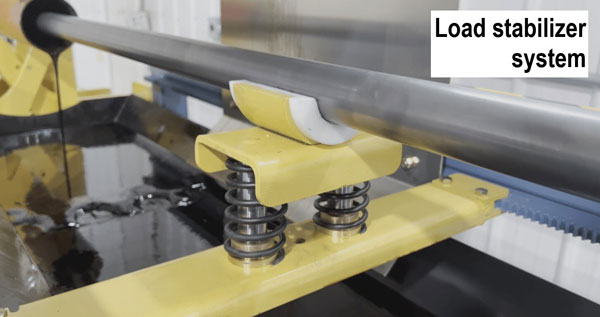

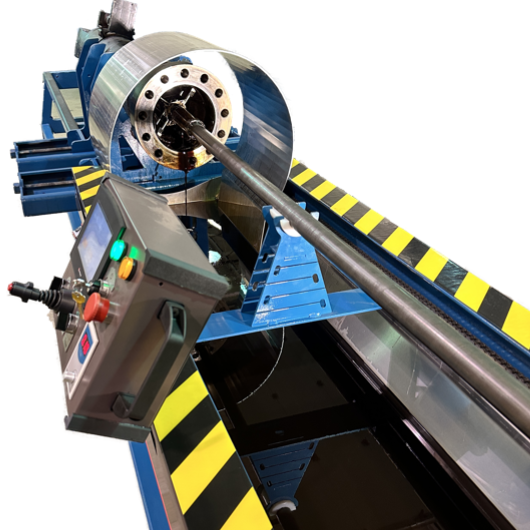

SELF-CENTERING MECHANISM AND WORK HOLDING SYSTEM

Regardless of the tube size, this system allows rapid setup and ensures the tube is centred after clamping.

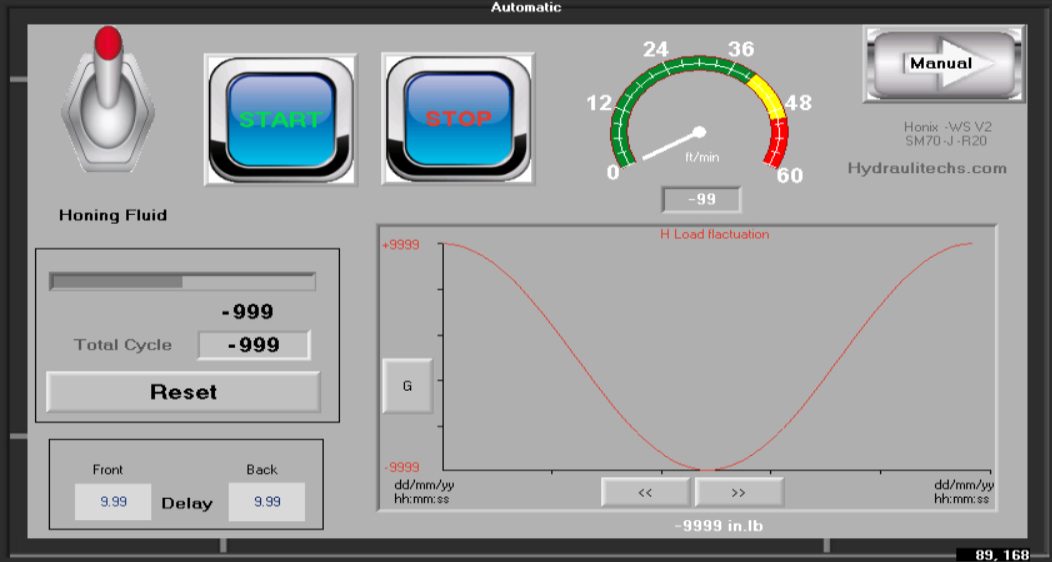

PLC CONTROLLED TOUCH SCREEN WITH LOAD GRAPH AND MANUAL BUTTON

Load graph displays the load along the honing shaft during the strokes. This helps indicate locations of the tight bore spots.The manual stroker is available on the PLC to allow the operator to move the honing tool over the stroke length, to set the ends of the stroke during setup process.

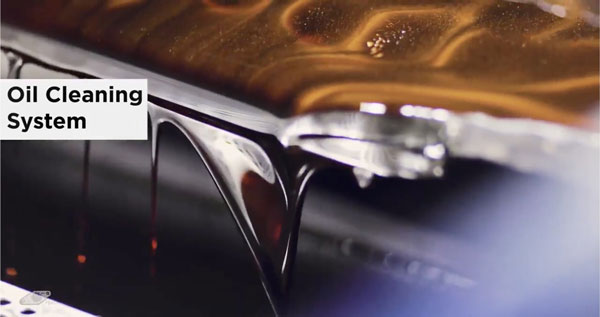

HIGH QUALITY HONING OIL FILTRATION

The 3-stage filtration system that includes magnets and paper media coolant filtration.

LAG TRANSITION ADJUSTMENT

Lag Transition Adjustment: Fine-tunes the transition at both ends of the strokes, enhancing the quality and consistency of the finish.

DIGITAL HONING LOAD ADJUSTER

Allows precise adjustments to the honing load, ensuring the honing media maintains constant pressure contact with the tube throughout the entire honing process.

ROTATING MESH SPLASH GUARD

A steel mesh is integrated into the splash cover to control oil splash. The mesh rotates upon contact with the cylinder, providing consistent splash control while accommodating different tube sizes.

PORTABLE REAR OIL TRAY

A movable oil tray is positioned at the rear side of the machine for honing open-ended tubes. The tray features wheels for easy repositioning and effective collection of excess oil from the back of the cylinder.

The benefits of fully automated tube honing include increased efficiency, repeatability, and the ability to handle large volumes of production with minimal human intervention. Automated systems can be programmed to adjust parameters such as feed rates, pressure, and tool movements, leading to a more streamlined and controlled manufacturing process.

Automatic honing for hydraulic cylinder rod finishing offers several advantages over manual methods, particularly in terms of efficiency, precision, and overall machining quality:

Consistent Precision

Automatic honing ensures a consistent level of precision in every cycle. The programmed parameters control tool movements, pressure, and feed rates, resulting in uniform and accurate surface finishes on hydraulic cylinder tubes.

Efficiency and Speed

Automated honing machines operate at higher speeds compared to manual methods. This increased efficiency allows for faster cycle times, enabling manufacturers to complete more honing processes in a shorter period.

Repeatability

Automatic honing systems provide high repeatability in the honing process. Once programmed, the machine consistently replicates the specified parameters, minimizing variations between different workpieces and ensuring uniform quality.

Reduced Labor Intensity

Automation reduces the reliance on manual labor for the honing process. This not only minimizes operator fatigue but also allows skilled workers to focus on more complex tasks, contributing to overall shop efficiency.

Optimized Tool Life

Automated systems can monitor and adjust parameters during the honing process, optimizing tool usage. This results in extended tool life, reducing the frequency of tool changes and associated downtime.

Enhanced Control and Monitoring

Automatic honing machines provide comprehensive control and monitoring capabilities. Operators can closely track parameters such as pressure, feed rates, and tool wear, allowing for real-time adjustments and ensuring consistent quality.

Adaptability to Various Materials

Automatic honing systems can be programmed to adapt to different materials and hardness levels. This flexibility is crucial for machining hydraulic cylinder tubes made from various alloys or materials.

Minimized Human Error

Automated systems reduce the risk of human error associated with manual honing. Precise control over the machining parameters helps avoid inconsistencies and variations that can occur with manual operation.

Improved Surface Finish

Automated honing consistently produces a high-quality surface finish on hydraulic cylinder tube. The precision control over the honing process helps achieve smoother surfaces, contributing to improved performance and longevity of the components.

In summary, automatic honing offers a combination of precision, efficiency, and control that outperforms manual methods in hydraulic cylinder tube finishing. This technology is well-suited for high-volume production environments where consistency and quality are paramount.