CYLINDER ROD POLISHER

AUTOMATIC / MANUAL MACHINE

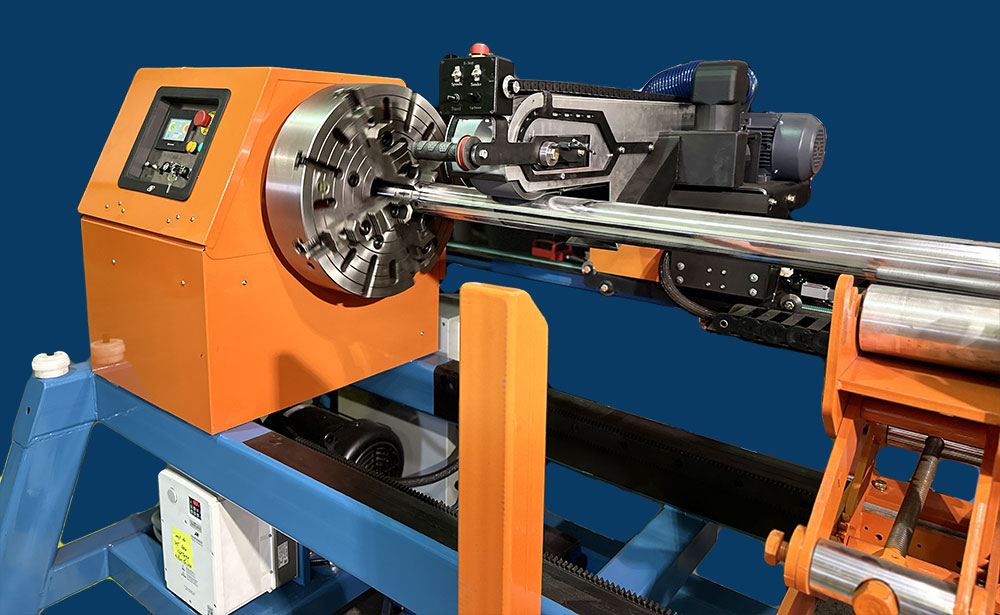

Automatic / Manual – APR-24/MPR-24 Rod polisher

APR-24/MPR-24 Rod polisher is a high-quality, reliable machine designed for efficient and precise polishing of rods. It features a manual and automatic Full PLC/VFD system, providing greater flexibility and ease of use. With a 7.5 horsepower, VFD controlled 1,750 RPM PMAC motor as the spindle drive, 3 horsepower, 3600 RPM sander drive and ¼ horsepower DC variable motor as the sander head travel drive, this machine allows for easy adjustment of the RPM of the rod, from 0 RPM to 300 RPM.

APR-24- Automatic Rod Polisher

MPR-24-Manual Rod Polisher

Economic option

PRODUCT BENEFITS

Efficient and Precise:

The APR-24/MPR-24 is designed for efficient and precise polishing of rods, ensuring consistent results every time.

Safe and User-Friendly

The machine features adjustable limit switches and rollers for safety, as well as an easy-to-use control panel.

Versatile

The frequency drive and adjustable sanding belt make this machine versatile for various polishing and repair jobs.

- VOLTAGE 360-460 V, 3 PH, 60 HZ

- AMP 20 AMP

- MAX LENGTH OF ROD 20 FT

- MIN LENGTH OF ROD 18 IN

- MAX EXTERNAL RODDIAMETER 15 IN

- MIN EXTERNAL ROD DIAMETER 1IN

- MAX ROD WEIGHT 10,000 LB

- MAX WIDTHOF EYE ON ROD 12.5 IN

- MAX DIAMETER OF EYE ON ROD 24 IN

- – VOLTAGE PMAC7.5 HP WITH VFD for APR-24 model and 2.5 HP for MPR-24 model

- SPINDLE SPEED CONTROL RANGE 0 TO 300 RPM

- MODEL GATOR20″

- DIAMETER 20 IN

- NUMBER OF JAWS 4 INDEPENDENT

- BELTS 2 B102

- SIZE OF #6

- ADJUSTABLE YES

- LOCKING SYSTEM YES

- MOTOR 3 HP, 3450 RPM

- SAND BELT WIDTH 4 IN

- DUST COLLECTION PIPE 3 IN , APR-24 model – no dust collector for MPR-24 model

- SAFETY COVER YES

- AUTOMATIC & MANUAL YES

- SANDER ENGAGEMENT ELCTRO PNEUMATIC

- SANDER PRESSURE CONTROL YES

ELECTRICAL BOX and PLC CONTROL PANEL

- FUSE 6A

- FUSE 3A

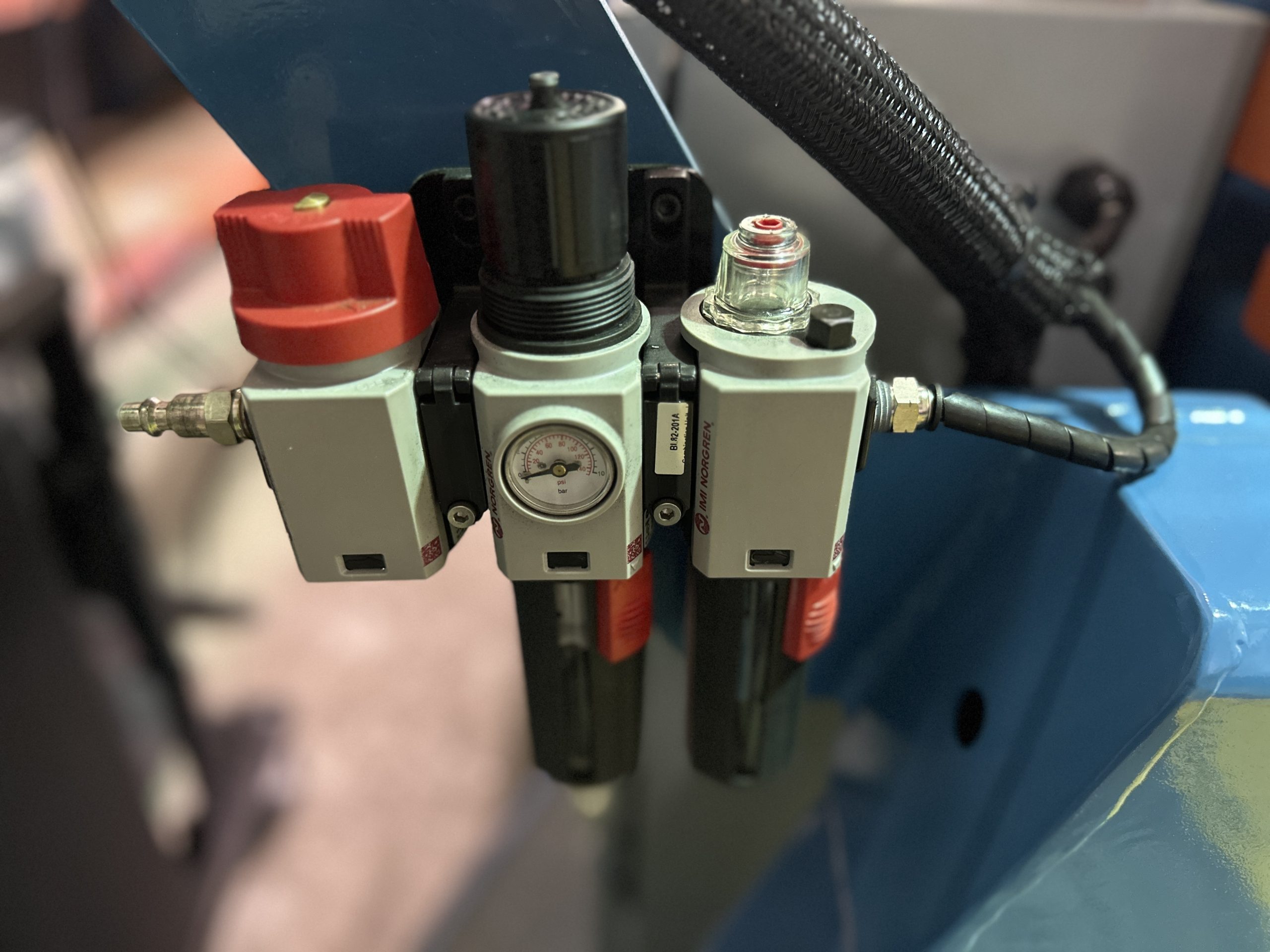

AIR CONTROL UNIT

- AIR SYSTEM LUBRICATION OIL

SANDER BELT

- 4″ * 90″ ALUMINUM OXIDE SANDER BELT

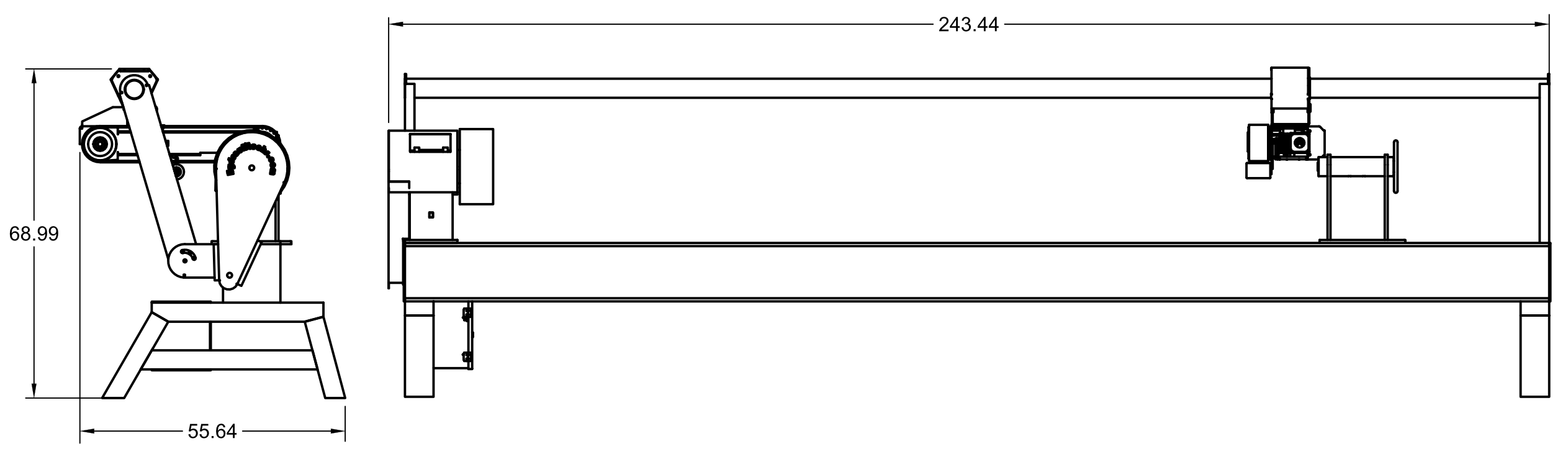

ROD POLISHER DIMENSIONS

- APR-24 – ROD POLISHER TOTAL LENGTH 29 ft

- MACHINE HIGHT WHEN SANDER IS IN THE HIGHEST 102 IN

- MACHINE WIDTH 70 IN

Rod Polisher Features

Polishing Head

The polishing head can be used in either automatic or manual mode, and features a hood protecting the operator from pinch points. There is also a 3″ diameter port to connect the dust collecting system.

Dust Collecting Cover

The dust collecting cover attachable to an external dust fan helps to keep the workspace clean and free of debris.

Position Adjustment Limit Switch

The position adjustment limit switch allows for accurate positioning and prevents over-polishing.

Electro Pneumatic Sander Engagement

The device’s electro pneumatic sander engagement ensures precision and consistency during the polishing process.

Electrical Cabinet / Control Cabinet

The APR-24 features a NEMA electrical cabinet with overload protection and stop/start buttons, as well as an emergency push button for safety.

Automatic / Manual Feed System

The APR-24 features an automatic/manual feed system for greater control and flexibility.

Cycle Counter Control

One of the key features of the APR-24 rod polisher design is the ability to set the automatic polishing cycle number conveniently through a user-friendly touch screen.

Sander Pressure Control

The sander pressure control allows the user to adjust the pressure for optimal polishing results.

Chuck and Tail Head Design

The chuck on the left and tail head on the right end side, with a chuck design of 4 independent jaws and a diameter of 20″. The chuck and tail head are both fixed in height, and the tail stock accepts tapper shank morse #6.

Manual and Automatic full PLC/VFD System

The APR24 features a manual and automatic PLC/VFD system, providing greater flexibility and ease of use.The PLC can handle complex control sequences and logic, while the VFD can provide adjustable motor speeds, enabling operators to optimize the polishing operation for different types of rods or desired finishes.

Emergency Stops and safety guards

The emergency stops and safety guards ensure safety during operation.